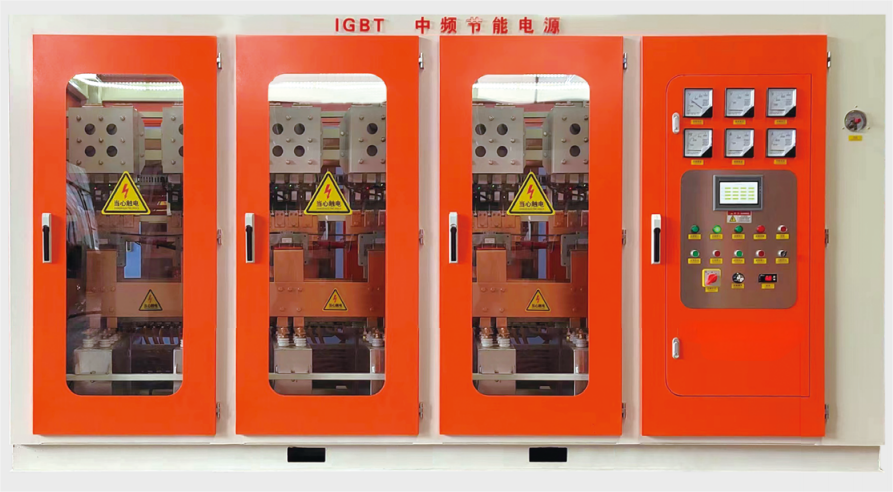

The IGBT Medium Frequency Furnace is an advanced induction melting system that uses Insulated Gate Bipolar Transistor (IGBT) technology to achieve high-efficiency, fast, and uniform melting of various metals such as steel, iron, copper, and aluminum. Featuring a full-digital control system, it offers precise temperature control, stable performance, and multiple automatic protection mechanisms. This furnace is ideal for metal casting, alloying, foundries, recycling, and research labs. Its modular design, high energy efficiency, and compact footprint make it the ideal solution for medium-sized metal processing enterprises seeking reliable and intelligent melting solutions.

Provides stable operation, high conversion efficiency, and low harmonic distortion.

Integrated PLC and HMI ensure real-time monitoring, fault diagnostics, and user-friendly operation.

Simplifies installation, maintenance, and supports future upgrades.

Includes over-voltage, over-current, water pressure, and temperature protection.

The IGBT Medium Frequency Furnace is a digitally controlled induction furnace optimized for melting a wide range of ferrous and non-ferrous metals.

Powered by IGBT inverter technology, it delivers fast, efficient, and uniform heating with minimal power loss. Its integrated digital control system ensures intelligent operation, while multiple safety protections and water-cooling systems enable reliable performance even under heavy-duty conditions. Available in both tilting and stationary models, this furnace is widely used in foundries, recycling plants, and precision alloy production.

The IGBT Medium Frequency Furnace is designed to meet the needs of various industries, providing a versatile and robust solution for metal melting.

Power Output: Ranges from 50kW to 3000kW, catering to different production capacities.

Melting Capacity: Capable of melting 50kg to 10 tons of metal per cycle, depending on model.

Cooling System: Equipped with a closed-loop water-cooling system, maintaining optimal temperature control for consistent performance.

Efficiency: The furnace provides 10-20% more energy efficiency compared to traditional models.

Melting Time: Typically melts 1 ton of metal in under 60 minutes, depending on the metal type.

Payment Methods: We accept bank transfer (T/T) and Letter of Credit (L/C).

Delivery: Delivery time is typically 30 days from order confirmation, depending on custom requirements and production schedules.

Packaging: The furnace will be securely packaged to ensure safety during transport, with all components carefully packed to avoid damage.

Shipping: We offer FOB, CIF, and other international shipping methods based on customer preferences.

Consumes 10-20% less power, reducing operational costs.

Reduced downtime and repair costs, thanks to the durable IGBT technology.

Melts up to 1 ton of metal in approximately 60 minutes, boosting production rates.

Custom solutions available to accommodate various metal types and melting capacities.

IGBT technology ensures consistent melting with minimal fluctuation in temperature.

Lower energy consumption and reduced emissions.

IGBT Medium Frequency Furnaces are widely used in industries such as metal casting, machinery manufacturing, metal recycling, precision alloy production, and scientific research. They are capable of melting steel, iron, copper, aluminum, brass, stainless steel, precious metals, and more.

Due to their high melting efficiency, precise control, and eco-friendly design, these furnaces are ideal for producing high-quality castings, refining recycled metals, and conducting small-batch alloy experiments. Their versatility also makes them suitable for producing automotive parts, aerospace components, electronics, and specialty metal products.

The furnace’s compact footprint and low noise make it especially suitable for clean, modern production environments.

Over 20 years of industry experience in manufacturing and providing high-performance melting solutions.

IGBT technology ensures high efficiency, low maintenance, and increased reliability.

Products are sold in over 60 countries, ensuring we can meet the needs of international customers.

Full-service customer support, from installation and maintenance to technical assistance.

The furnace can melt 1 ton of metal in less than 60 minutes, depending on the type of metal.

It can melt steel, aluminum, copper, and various alloys, including precious metals like gold and silver.

The furnace is up to 20% more energy-efficient than traditional furnaces, helping to reduce costs.

Yes, the furnace is designed for low maintenance, with durable components and easy-to-replace parts.

The furnace comes with a 1-year warranty and lifetime technical support.

Yes, the furnace is available in different configurations, such as tilting or holding, and can be tailored for various metal types.

The furnace uses a closed-loop water cooling system, which is included in the package.

Delivery typically takes 30 days after order confirmation, depending on customization.

The furnace can melt up to 10 tons of metal per cycle, depending on the specific model.

Yes, it is designed for continuous, high-performance operations and can handle heavy-duty industrial environments.

Get Quotation Immediately