Your cart is currently empty!

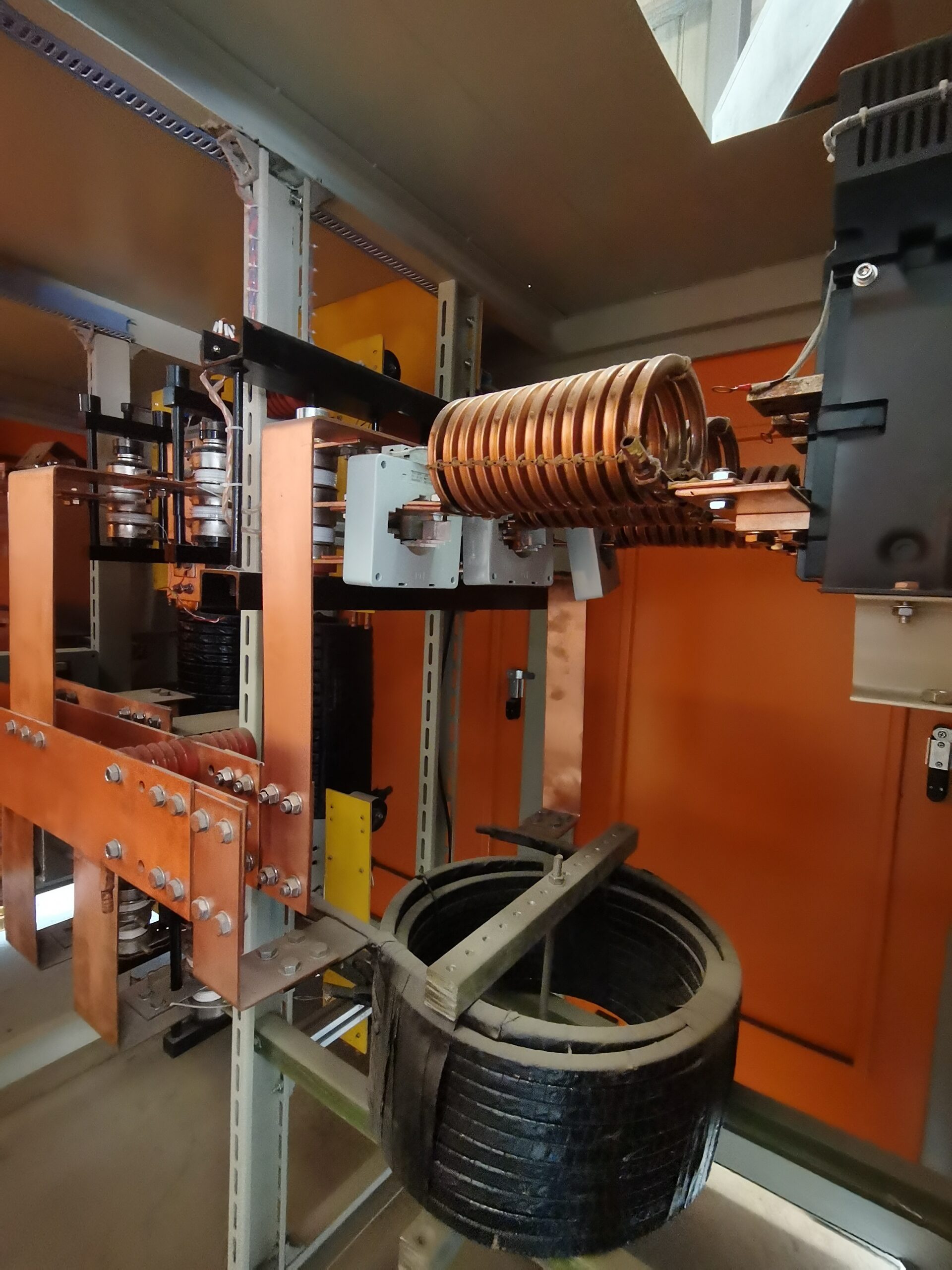

Medium Frequency Power Supplies (MFPS) have become a critical component in modern industrial processes. These power supplies are designed to convert high-frequency electrical energy for a wide range of applications, including induction heating, metal melting, hardening, and more. With the growing demand for efficiency, precision, and energy-saving solutions, the use of MFPS is increasingly prevalent in various industries.

What is a Medium Frequency Power Supply?

A Medium Frequency Power Supply is a device that converts electrical energy from the standard AC grid into medium-frequency electrical power, typically within the range of 1 kHz to 100 kHz. These power supplies are commonly used in applications where efficient heat transfer and precise control are required.

By operating at medium frequencies, these power supplies enable faster heating and higher energy efficiency, compared to traditional low-frequency power supplies. The ability to deliver high-frequency power to industrial equipment provides more consistent and reliable results in processes such as metal heating, welding, and forging.

Key Features of Medium Frequency Power Supplies

- High Efficiency

One of the most significant advantages of MFPS is their high efficiency in converting electrical power into usable energy. This not only reduces energy consumption but also minimizes heat losses, making them an ideal choice for energy-conscious industries. - Precise Control

MFPS provide excellent control over the frequency and power output, allowing for precise control of heating processes. This is especially important in metal melting, surface hardening, and other applications where exact temperature control is crucial. - Compact Design

Many modern medium-frequency power supplies are designed to be compact and modular, making them easier to install and maintain in a variety of industrial settings. Their smaller footprint is a significant advantage in industries where space is at a premium. - Enhanced Durability

The robust design and high-quality materials used in MFPS ensure their durability even in the harshest industrial environments. Whether in steel manufacturing or metalworking, these power supplies can withstand extreme conditions and operate reliably over extended periods. - Versatility

MFPS can be used in a wide variety of applications, including induction heating, hardening, melting, and brazing, making them incredibly versatile tools in industrial processes.

Applications of Medium Frequency Power Supplies

- Induction Heating

One of the most common applications of MFPS is in induction heating, where they are used to heat metals for forging, hardening, and other processes. The high-frequency power generated by the MFPS induces electrical currents in the metal, creating localized heating that is both efficient and precise. - Metal Melting

In metal foundries, MFPS are used for melting metals such as steel, aluminum, and other alloys. The high-frequency power provides rapid and uniform heating, ensuring the metal reaches the desired temperature for casting. - Surface Hardening

MFPS are widely used for surface hardening of metals, particularly in the automotive and aerospace industries. By applying localized heat to the surface of metal components, these power supplies help achieve the hardness required for parts that undergo high wear and tear. - Welding and Brazing

The use of MFPS in welding and brazing applications allows for faster and more reliable joining of metals. The precise control of heat ensures high-quality welds and braze joints, reducing the chances of defects and ensuring stronger bonds. - Heat Treatment

Medium frequency power supplies are also used for heat treatment processes such as annealing and tempering. By providing accurate and consistent heat, they improve the mechanical properties of metals and ensure their suitability for a variety of end uses.

Why Choose Medium Frequency Power Supplies?

- Energy Efficiency

MFPS offer superior energy efficiency compared to traditional low-frequency power supplies, helping reduce operational costs and environmental impact. - Improved Productivity

With faster heating times and more precise control, MFPS can significantly increase the throughput of industrial processes, leading to improved productivity and reduced cycle times. - Cost-Effective

While the initial investment may be higher, the long-term cost savings achieved through increased energy efficiency and reduced downtime make MFPS a cost-effective solution for many industries. - Customizability

Medium frequency power supplies can be customized to suit specific industrial applications. Manufacturers often offer tailored solutions that meet the unique requirements of individual customers, ensuring optimal performance for each application.

Conclusion

Medium Frequency Power Supplies are essential for industries looking to improve efficiency, precision, and productivity in various heating and metalworking processes. Their versatility, energy efficiency, and reliable performance make them a preferred choice for many industrial applications.

If you are considering incorporating a medium frequency power supply into your operations, contact us today to get a customized solution that meets your needs.